- #Deskcnc controller how to#

- #Deskcnc controller manuals#

- #Deskcnc controller 64 Bit#

- #Deskcnc controller driver#

#Deskcnc controller driver#

Moral: you can use a driver that works with the parallel port by connecting it to the computer with the USB port, but you have to use the specific program Theremino CNC (very simple and functional program), very important thing is that you only spent about 10 euros for the module ( I recommend that you buy it directly on their site Thereminostore ), so you are no longer bound to the desktop computer with parallel port and 32-bit operating system (I'm talking about if you use the Mach3 program).Īll the features of the Theremino CNC program can be found on the site, as well as the description of the best operational features of Theremino compared to Mach3 on parallel port, if you want to use this system, I recommend you create the toolpaths without the G02 and G03 commands, because, from tests done, sometimes they can give problems on some computers, rest assured, you can "live" without these commands.

#Deskcnc controller 64 Bit#

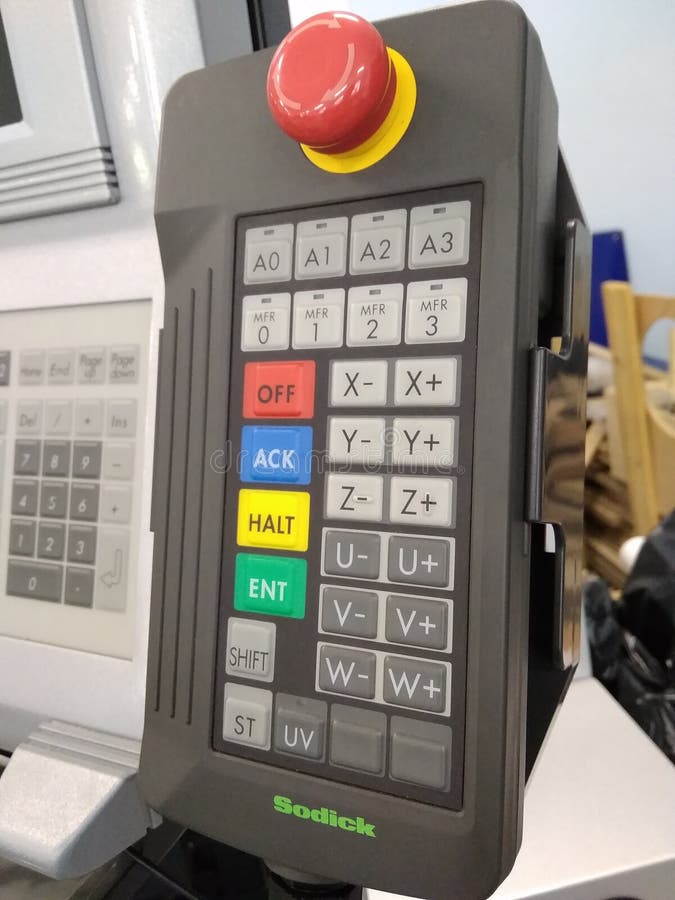

Summarizing the features of Theremino, I can tell you that this module connects via USB port to the computer (Windows 7, 8 and 10 32 or 64 bit operating system), and then, with a simple connection to an LPT connector, you can connect directly to the electronic driver which is designed to work with the parallel port of the computer, see photo on the left. The considerations I put for each program are obviously personal and are deduced from the type of use for which I use the programs.

You might as well have bought a nice and small subcompact, easy to use and that moves well in traffic (stupid comparison, but I think it gave you the idea of what I wanted you to understand).

#Deskcnc controller how to#

It is like buying a Ferrari car to use in cities with heavy traffic: you have paid dearly for it, you will certainly not go fast and perhaps you do not even know how to drive it. The high speed is often of no use to you, especially if you have to machine hard materials with small diameter cutters! Speed is not the most important thing to consider, also because this could be influenced by the type of computer you use (processor, RAM memory, working frequency), by the type of operating system installed on it (W98, WXP, Linux), the type of stepper motors installed in the cutter and the power supply voltage they work with as well as dozens of other reasons. I often read in the forums that the "Tizio" cutter control program is much better than "Caio" because the cutter is faster. They are made by people who are certainly capable and of good will, they also have these continuous updates and are suitable for use in a very wide spectrum of applications.

#Deskcnc controller manuals#

The cutter control programs for a more hobby and amateur use, have a much lower cost (about 100 euros or even free), are not very complex and can be learned to use alone or thanks to small user manuals attached to them.

They have many features and often the program is customized according to the type of processing to be performed (typically mechanical or artistic processing). I remember that all these software programs can be of a professional type, ie aimed at those who use them for work and on "real" numerical control work centers (CNC), and they certainly have high costs (from a thousand euros upwards), they require a lot commitment to be able to use them at their best and often a training course in their use is required.

0 kommentar(er)

0 kommentar(er)